MAPRO - SMOOTH GAS AND AIR TREATMENT

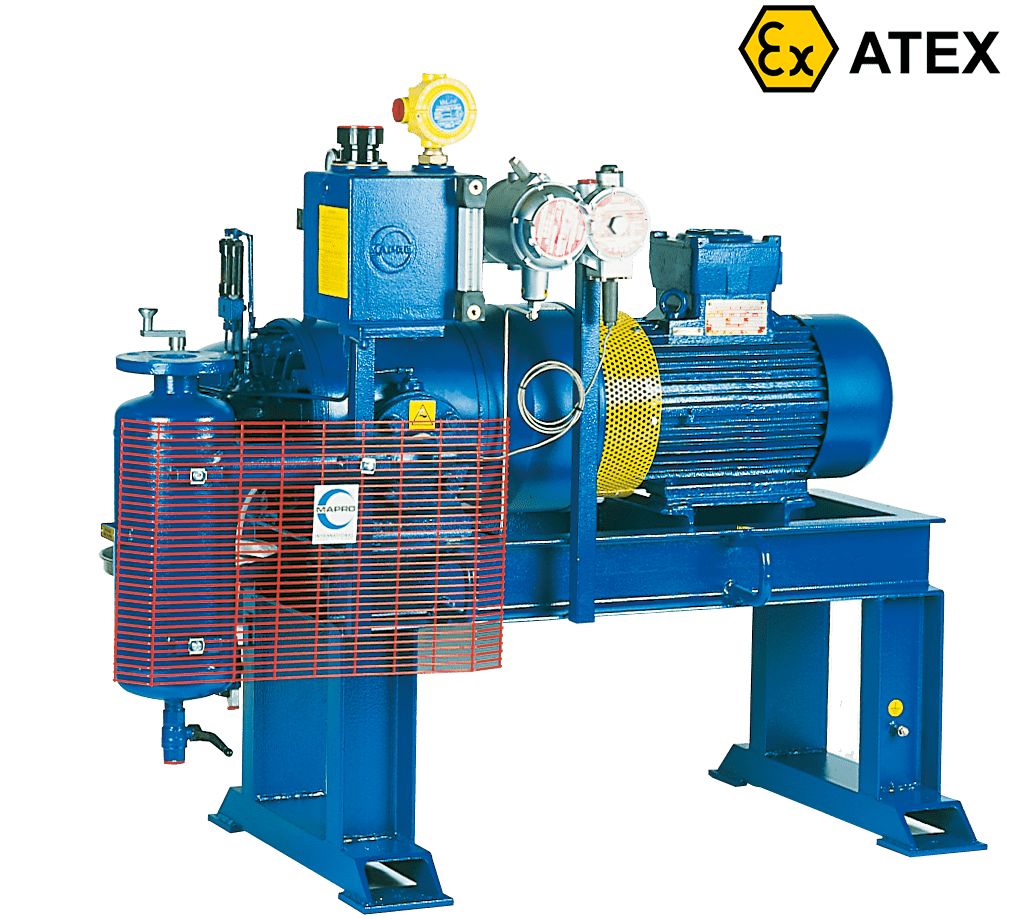

“Mapro International” is an international group of gas and air treatment firms that we represent. Mapro International S.p.A. has been producing air and technical gas treatment systems since 1959. The company’s mission is to build rotary vane compressors and vacuum pumps for the pumping and compression of gaseous liquids, particularly corrosive liquids. Our collaboration in delivering compressors and vacuum pumps to Lithuania and other Baltic nations properly achieves these objectives. These machines are utilized in a variety of industrial sectors, ranging from food to pharmaceuticals, molding to packing machines, manufacturing facilities, pollution control, and more. This enables our company to supply solutions for any technical air or gas transfer procedure that are technologically acceptable for usage today and will stay dependable beyond time.

EQUIPMENT AND APPLICATION:

- Centrifugal fan: a type of fan used to collect or compress combustible gases such as biogas or natural gas. Because the rotating pieces do not come into contact with the body during rotation, there is no friction during operation, and no internal lubrication is required. The gas passing through the apparatus is clean and devoid of oil contaminants. Advantages: simple installation; low noise level; no vibration; smooth gas flow; little maintenance required.

- A rotary compressor with a sliding vane is high-efficiency working-volume equipment. Used for recirculation of biogas to anaerobic digesters for sludge mixing, extraction of biogas from landfills to storage systems or supply to engines, and extraction of natural gas from pipelines and supply to storage systems or engines. Advantages: The limited number of moving components facilitates compressor disassembly and assembly, making these processes far less expensive when compared to other types of displacement devices. Because the gas flow is constant (without pulsation) both at the intake and at the output, no storage tanks or gas valves are required.

- Side-channel blowers are used to collect or compress combustible gases like biogas or natural gas. Designed to comply with Directive 2014/34/EU Equipment Group II, Category 2 for environmental conditions and machine internals. The major benefits of adopting side channel blowers are: simple installation; low noise level; no vibration; smooth gas flow; and low maintenance. Furthermore, no internal lubrication is required, so the gas passing through the unit is not polluted by oil.

- Centrifugal blowers with many stages that may achieve speeds of up to 6000 rpm. A variety of impeller designs, the possibility to link many stages in sequence (up to 10) and a wide range of rotation rates. During operation, there are no related creep portions. Because there is no friction, no lubrication is necessary, and so the supply air is not polluted. Furthermore, multistage centrifugal blowers have the following advantages: quick installation; low noise level; no vibration; gas flow without pulsation; no gas pollution; and little maintenance.

- Positive Displacement Blowers: Ideal for all applications that require much greater flow rates than side channel blowers. A flow rate of up to 4200 m3/h and a discharge pressure of up to 1000 mbar g are achievable. The most prevalent applications are: air injection into oxidation tanks of wastewater treatment facilities; pneumatic transportation; and pumping air into saturated soil to increase pollutant biodegradation. The rotating components of the blower do not come into contact with each other during operation. As a result, no friction exists between the two rotors or between the rotors and the stator, and no internal lubrication is necessary. The gas passing through the equipment is fully oil-free and uncontaminated.